Glowforge Review: Lasers Lasers Pew Pew Pew

I’d say about twice a week someone on Instagram asks me to tell them about how my Glowforge (I named him Dash) is working out, and if it was a good investment for my business. It’s time to put my thoughts about Dash down here so I can start responding with a link to my blog post and save my poor thumbs for hand sewing.

A Glowforge uses a teeny tiny laser beam to cut and/or engrave materials like wood, acrylic, leather, paper, and fabric. You connect the machine to your computer through Wifi, and use the Glowforge software to set up the material specifications, place the designs on the material, and enter commands for each cut. You will do all your designing on your own software (I use Illustrator).

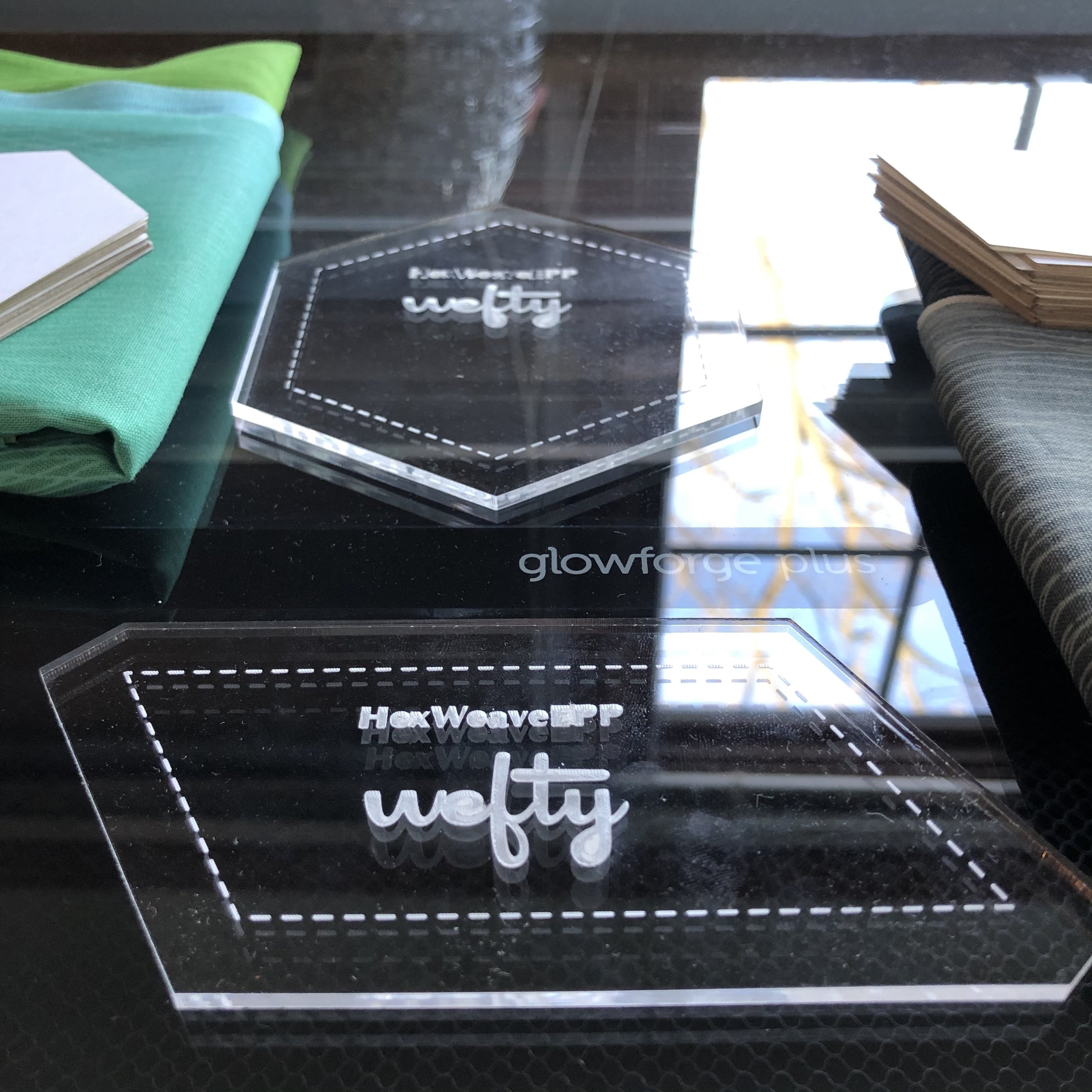

I have engraved and cut keychains with mine and others’ company logos on them, little charms with drawings by my daughter on them, acrylic templates for a friend, wooden embroidery hoops, needle minders, papers for English Paper Piecing, and even acrylics and papers for my own English Paper Pieced design. My first print was the day after I set Dash up, that’s how easy it is to get started. I’m a big fan and I’m excited to play more.

Use my discount code if you’ve already made up your mind and are just here for the dirt (I see you. I feel you. I respect you.)

Wooden Embroidery Hoop and Needle Minder using a design from Steph Skardal.

Answers to Popular Questions

Him’s a Big Boy. The footprint of a Glowforge is 38 inches wide, 20.75 inches deep, and 8.25 inches tall. I have Dash on his own table.

He’s gassy. You will need to attach a hose and aim the hose out a window or door. My husband built a window attachment that makes this almost airtight. If you don’t have great ventilation, you will regret it. There is a filter attachment you can buy, but I didn’t believe it would be better than what we could build (oh the ego, yeah?), plus for just under $1,000 do I even have to finish this sentence? Probably not. You feel me.

Important: You can NOT cut or engrave vinyl or plastic.

Money Money Money: What folks seem to want to know about the most is if it’s lucrative. I assume people are asking me if Dash has paid for himself and made me some profit. Nope. I don’t imagine he will. Dash is a Glowforge Plus, the mid-model. The Glowforge Pro is the model made for all-day use and large prints, so it’s the only machine that would be able to withstand the demands of manufacturing in order to make me some money (assuming anyone wanted to buy what I was cutting, obviously). At just shy of $6000, what I’m cutting would need to be in demand in order for me to start turning a profit. As I was trying to decide between the Plus and the Pro, I just couldn’t guarantee myself that I would be incorporating laser cutting into my business, and I definitely didn’t want to turn cutting and engraving into a tedious job where I babysit the machine all day. I wanted the machine for learning, play, and developing prototypes. Thus, I decided the Plus was for me. No regrets!

Cutting for Others: This is one way to help pay for a laser cutter. However, the files people send you would need to be ready for the cutter - meaning they would need to know how to design for a laser cutter and send you a ready-to-print file. Otherwise, the hours you spend re-designing what they send you will quickly add up. I found that I was spending a lot of time reformatting and designing peoples’ files, then one gal sent me a ready-to-print file and I realized immediately I wouldn’t be messing with the former type of files ever again. Ready-to-print or bust. Sorry, folks!

My Advice for You

I’m not going to pretend to not want to tell you what to do. Here’s what you should do:

If, like me, you have wanted a home laser cutter for years and this is the first time you’ve had enough money saved up for it, get that sucker. Have fun. Use my discount code for $500 off a Pro, $250 off a Plus, or $100 off a Basic. Make lots of time lapse videos.

If you are wanting some way to make your own templates, rulers, or other products but don’t know if this is the investment you want to make, don’t even worry about it! There are so many ways to get prototypes made for you - and even to get products made for your shop. I have used Ponoko to have acrylic template prototypes made. Their software for designing something yourself is really easy to use and I had fun doing it. Their work is really nice looking. I have also worked with Laser Cut Quilts and they would be my first stop were I looking to have a product made for my shop. They’re amazing to work with and a small business very deserving of lots of support. They can cut any design for applique out of fabric, and it comes already fused to their special fusible interfacing, ready to be placed on a background. They cut paper, cardboard, and acrylics as well.

I think I’ve covered everything I know. To find out lots more, check out the Glowforge site. As an owner, I have a log in, access to the community forums (which have been really helpful and interesting to read), and a design catalogue. It’s a great site with a ton of great information.

I hope this has been helpful. Leave questions for me in the comments and I’ll get to them here or in a follow up post.

Whatever you’re working on, I hope it’s meaningful and rewarding for you!

This post may contain affiliate links for those products I use and believe in.